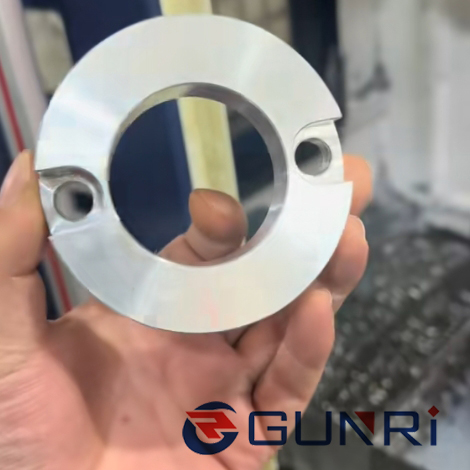

Limit rings, also known as shaft collars, retaining rings, or snap rings, are critical components in factory automation systems. They serve as positioning, alignment, and locking mechanisms for shafts, bearings, and other mechanical parts. Despite their simplicity, these rings are prone to failures that can disrupt production efficiency and compromise equipment reliability. Drawing insights from industry practices and technical documentation, this article explores the most frequent issues affecting limit rings, their root causes, and actionable solutions for procurement and maintenance.

Material Degradation and Corrosion

Problem:

Limit rings made from low-grade carbon steel or untreated aluminum often corrode in humid or chemically aggressive environments. For instance, unprotected steel rings may develop rust, leading to surface pitting and eventual fracture under stress.

Root Causes:

• Inadequate Material Selection: Non-corrosion-resistant alloys (e.g., untreated carbon steel) are used in environments with moisture or chemical exposure.

• Surface Treatment Flaws: Incomplete plating (e.g., thin nickel coatings) or improper oxidation processes (e.g., uneven anodizing on aluminum) accelerate degradation.

Case Study:

A food packaging plant reported frequent limit ring replacements due to rust-induced jamming. Switching to SUS304 stainless steel rings with electropolishing resolved the issue, reducing downtime by 40% .

Mechanical Fatigue and Fractures

Problem:

Repeated stress cycles from high-speed machinery or heavy loads cause cracks in thin-walled or improperly heat-treated rings. For example, snap rings in conveyor systems often fracture at the base after months of operation.

Root Causes:

• Weak Material Hardness: Substandard spring steel or non-hardened alloys fail under cyclic loads.

• Design Flaws: Thin cross-sections or abrupt geometric transitions create stress concentrations.

Mitigation Strategy:

Adopting quenched and tempered spring steel (e.g., SAE 1095) with a hardness of 45–50 HRC improves fatigue resistance. Finite element analysis (FEA) during design can optimize stress distribution .

Improper Locking and Loosening

Problem:

Locking mechanisms like set screws or clamps may slip, causing axial misalignment. This is common in vibration-prone environments, such as CNC machines or robotic arms.

Root Causes:

• Low Friction Coefficients: Smooth surfaces on aluminum rings or unlubricated steel rings allow unintended movement.

• Inadequate Clamping Force: Undersized set screws or oversized threads fail to generate sufficient friction.

Solution:

• Use split-lock washers or serrated flanges to enhance grip.

• Implement thread-locking adhesives (e.g., Loctite 243) for permanent installations .

Noise and Vibration Issues

Problem:

Metal-to-metal contact between rings and shafts generates audible noise and accelerates wear. This is problematic in precision equipment like medical devices or audio machinery.

Root Causes:

• Lack of Buffering Layers: Solid rings without rubber or polymer inserts transmit vibrations directly.

• Poor Surface Finish: Rough edges or burrs increase friction and noise.

Design Improvement:

Integrate a 0.5–1 mm thick urethane or nylon bushing between the ring and shaft. For example, a Japanese automotive supplier reduced noise by 20 dB by adding a TPU insert .

Installation and Compatibility Errors

Problem:

Incorrect sizing or mismatched tolerances lead to improper seating. A logistics automation company faced repeated belt misalignment due to rings with ±0.1 mm dimensional deviations.

Root Causes:

• Tolerance Stacks: Cumulative errors from shafts, bearings, and rings exceed allowable limits.

• Incompatible Standards: Mixing metric (e.g., DIN 471) and imperial (e.g., ANSI B18.2.1) components.

Procurement Checklist:

• Verify tolerances using ASME Y14.5 standards.

• Opt for modular systems with integrated mounting holes for alignment .

Guidelines for Selecting High-Performance Limit Rings

- Material Selection Matrix EnvironmentRecommended MaterialSurface TreatmentHigh HumiditySUS304 Stainless SteelElectropolishingHigh TemperatureInconel 718Oxidation CoatingCorrosive ChemicalsHastelloy C276Passivation

- Locking Mechanism Types

• Set Screw Type: Cost-effective but prone to loosening. • Serrated Flange: Balances cost and grip strength. • Clamp-On Design: Eliminates tool use for quick changes. - Supplier Evaluation Criteria

• ISO 9001/TS 16949 certification for quality assurance. • Prototyping support for custom geometries. • Batch testing reports (e.g., salt spray, fatigue cycles).

Conclusion

Limit rings may seem minor, but their failure can cascade into costly downtime. By addressing material science, design rigor, and supplier collaboration, manufacturers can ensure these components meet the demands of modern automation. As the industrial sector evolves toward Industry 4.0, investing in smarter, more durable limit rings will remain pivotal for operational excellence.

For further technical specifications or procurement guidance, contact us