In the realm of industrial pc for machine vision, an array of sophisticated technologies converge to form the backbone of rail transit vision systems. These include image processing, mechanical engineering, control theory, electric light source lighting, optical imaging, sensor technology, and both analog and digital video technologies. The seamless integration of such disciplines lays the groundwork for an intelligent and automated rail transit vision monitoring system, with the industrial pc for machine vision acting as a central hub for data processing and analysis.

The components pivotal to the rail transit vision system are as follows:

Industrial cameras: Capturing images that serve as the eyes of the system.

Light sources: Illuminating the scene to ensure image clarity.

Image analysis software systems: Extracting valuable insights from visual data.

Industrial PCs (IPCs): Coordinating the system’s operations with robust computing power and reliability. The industrial pc for machine vision is indispensable for the precise monitoring and swift response of the vision system.

Specifically designed for rail transit, the high-speed gigabit Ethernet industrial pc for machine vision, equipped with an M12 aviation interface, offers several key advantages:

Safety and Reliability:

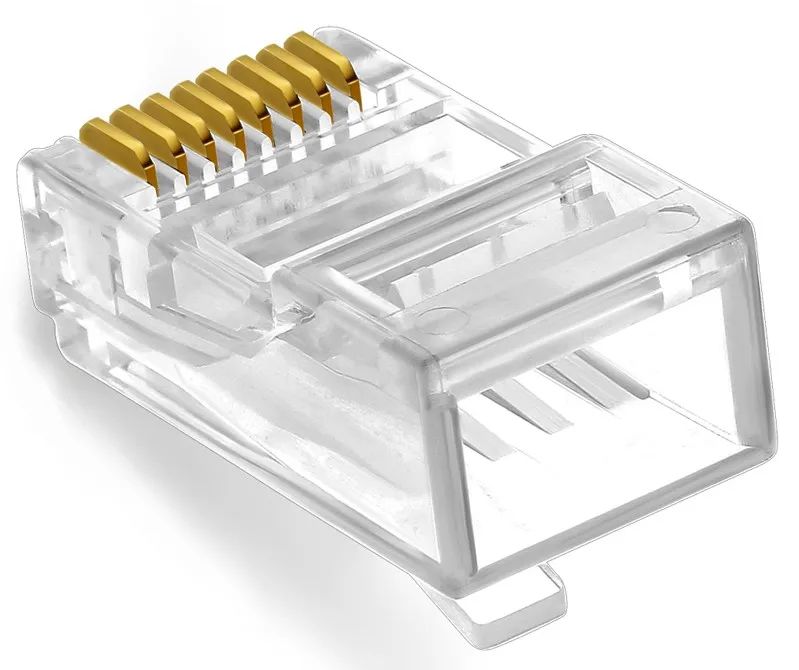

The M12 interface safeguards against plug damage or loss.

Rapid Response: The aviation interface’s quick connection/disconnection mechanism.

Ease of Installation: The aviation connector’s user-friendly design for efficient system setup.

High Reliability: Ensuring stable and dependable data communication even in high-vibration environments, such as those found in buses, subways, and high-speed trains.

The wired network port of the industrial pc for machine vision is fundamental to the system’s functionality, facilitating:

Data Transmission: Linking devices like servers, switches, and sensors.

Device Connection: Guaranteeing the integrity of data exchanges.

Network Management: Overseeing network protocols and operations.

Network Applications: Supporting software platforms and development essential to the IPC’s role, especially in scenarios requiring Power over Ethernet (PoE), where the M12 aviation interface excels.

The industrial pc for machine vision is versatile and valuable across various applications:

01 Rail Transit:

The industrial pc for machine vision is integral to rail transit’s data processing, handling real-time train operational data. Modern subway systems may utilize over 20 high-definition cameras per train, generating several gigabytes of video data per second for the IPC to process.

02 Smart Buses:

In smart bus systems, the industrial pc for machine vision enhances operational management, with equipped lines seeing a punctuality improvement of over 15% and a 20% increase in passenger satisfaction.

03 Automated Production Lines:

The industrial pc for machine vision’s precision control significantly boosts production line efficiency, cutting production time by approximately 30% and increasing output by more than 25%.

04 New Energy Vehicles:

In new energy vehicles, the industrial pc for machine vision enhances intelligence and safety, with BMS monitored by the IPC ensuring battery pack health and longevity.

For further insights into the world of industrial PCs and their applications in machine vision, reach out to GUNRI.