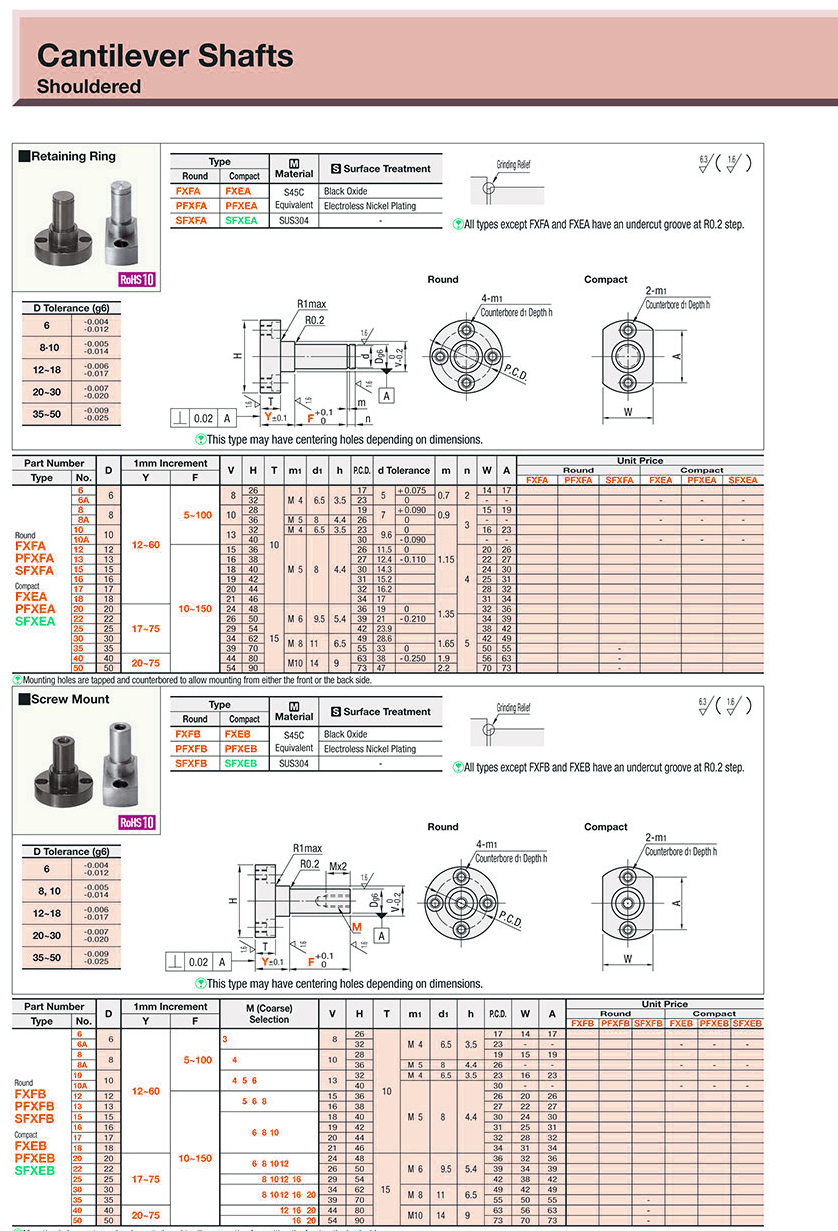

Cantilever Shafts – Heavy Load/Female Screw Type

Cantilever Shafts are mechanical transmission components that are fixed on one side and bear loads on the other side. They are specifically designed for heavy – load working conditions. The Female Screw Type refers to the structure with internal threads at the shaft end, which facilitates bolt – on connections with other components such as flanges, couplings, or actuators. It is suitable for high – torque and high – strength application scenarios.

Gunri - Professional a automation parts manufacturer

- ISO9001:2008

- JIS,AISI,DIN

- OEM Factory

Description